Aluminum extrusion production line

The company are equipped with two aluminum extrusion production lines, 1250t and 2200t. Full-automatic aluminum extrusion machines efficiently guarantee the manufacturing qualities and needs of aluminum extrusion products.

Cold stamping machine production line

More than 60 precision stamping machines and auto milling machines efficiently and precisely achieve the stamping techniques including punching, blanking, bending, coining, embossing, and flanging.

CNC machine centers

More than 70 high-precision and high-efficient CNC machine centers improve the company’s manufacturing capabilities and guarantee the products qualities and delivery. The FANUC and TSUGAMI CNC machine centers purchased from Japan satisfy the manufacturing needs of high-end products.

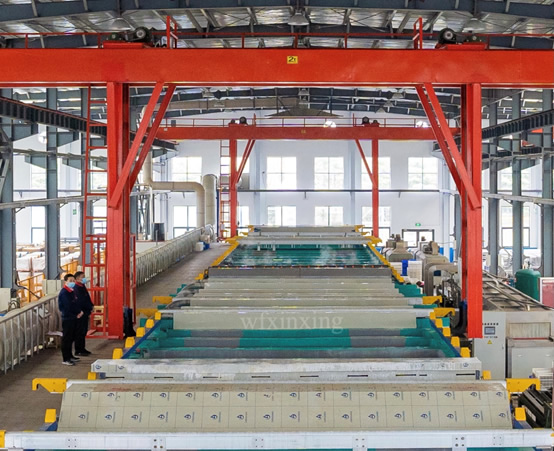

Surface treatment production line

The anodic oxidation production line fully satisfies the needs of surface treatment techniques of aluminum heatsinks.

Warehousing logistics center

Precise and efficient logistics management guarantees the on-time delivery and satisfies the customers’ needs.

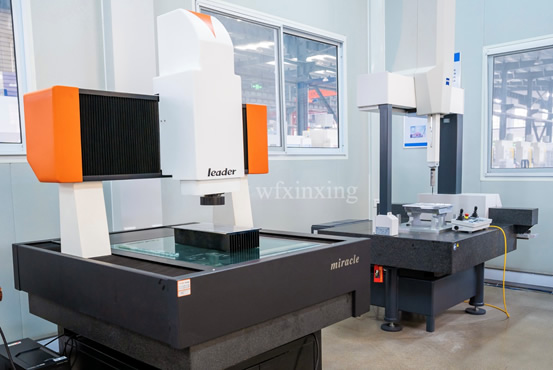

Quality control

The ZEISS Bridge Coordinate Measuring Machine has a faster and more precise measurement system. Other measurement instruments including optical metrology, tension test machine, roughness tester, hardness tester, coating thickness gauge, vernier scale and so on are all equipped for quality assurance.